Order Hotline: 01782 410381

New Morris Versimax HD18 5W-20 engine oil for Scania and MAN available from Premier Lubricants

Premier Lubricants is pleased to announce the launch of an innovative new engine oil for Scania & MAN, manufactured by Morris Lubricants.

Morris Lubricants has launched Versimax HD18 5W-20; a new grade of heavy-duty diesel engine oil that meets the precise requirements of the latest Scania and MAN fuel-efficient HGV engine technology.

With the first orders already despatched in just two weeks from initial enquiry, the new heavy-duty diesel engine oil complies with Scania LDF-5 and MAN M3977 specifications. This makes Morris Lubricants one of the first lubricant providers in the UK to commercialise this new ‘ultra-thin’ oil formulation for the haulage sector – a further demonstration of its lubricant innovation in commercial vehicle engine oils.

Readily available in 25 litre drums, 205 litre barrels and in bulk supply, Versimax HD18 5W-20 is already being used in the latest 13-litre Scania engines: DC13 173, DC13 174, DC13 175 and DC13 176. The engine oil can also be used in MAN D26 and D38 models.

As OEMs, commercial vehicle manufacturers and upstream technology providers move closer to Euro VII compliance, which is expected to be introduced around 2025, engine technology is evolving at pace. In the HGV diesel market, significant strides have already been made in reducing diesel particulates, carbon monoxide and NOx emissions in the exhaust gas stream, and now there is increased emphasis on reducing CO2 emissions, by improving fuel efficiency.

As a result, engine hardware is adapting, with examples including an emphasis on materials with increased strength and reduced weight, alongside a reduction in the number of cylinders required.

To deliver these improvements in fuel efficiency, engine oils have also needed to evolve. New, low viscosity formulations are emerging that reduce internal viscous drag, which in turn limits energy losses, improves overall engine efficiency and cuts CO2 output.

Adrian Hill, Morris Lubricants' Technology Manager explains the reasons behind the 5W-20 engine oil:

“The HGV market has witnessed significant changes in recent years, as internal combustion engines are developed for improved fuel efficiency and reduced CO2 emissions. 5W-30 heavy-duty diesel engine formulations are a commonplace option for the major OEMs, but as these companies innovate in the direction of Euro VII compliance, we will witness another step change in oil viscosity levels.

"This is the real difference with our new Versimax HD18 5W-20 heavy-duty diesel engine oil. It has reduced oil film thickness down to passenger car engine oil levels, but for use in commercial HGVs with payloads that clearly far exceed an average road vehicle.

“Inclusive of field trials, it can take years to bring new oils and lubricants to market, particularly engine oils. Here at Morris Lubricants, we have all the necessary raw materials in our inventory, to enable us to move quickly to meet customers’ demand.

“So, from identifying the initial market need, to assessing the required specification and undertaking our rigorous laboratory testing process, the Versimax HD18 5W-20 was manufactured and the first orders delivered in just two weeks.”

"Scania and MAN are the first OEMs to deliver fleets here in the UK, capable of using these specifications.”

About the Versimax range

The new Versimax HD18 5W-20 is part of the Versimax range, a series of approved, superior quality, heavy-duty diesel engine oils. These are manufactured at the Morris Lubricants facility in Shrewsbury.

The Versimax range is designed to help reduce downtime, improve fuel efficiency and contribute to the reduction in engine emissions. Used by fleet operators, maintenance technicians, mechanics, and drivers, Versimax engine oils help to rationalise usage where mixed fleets of vehicles and engine technologies are in operation.

Offering a range of oils that are suitable for previous and current generation of heavy-duty diesel engines, including those with aftertreatment devices, the Versimax range provides users with peace of mind.

Further information on the Versimax HD18 5W-20 including the TDS and product features and benefits can be found by clicking here.

Can Hydrogen combustion engines replace diesels in trucks

A very interesting article in Transport operator, highlighting the research currently being done into hydrogen combustion engines to determine if they can replace diesels in trucks.

Mainstream manufacturers are now investigating ways in which internal combustion engines can continue to power heavy-duty long-range applications beyond the UK government’s proposed 2040 ban on diesel trucks.

First out of the traps is DAF, which has a hydrogen-powered internal combustion truck undergoing track testing, although it says production versions are at least five years away.

The H2 Innovation Truck, based on a 4×2 XF tractor unit, uses a modified version of DAF’s 13-litre MX engine with direct fuel-injection, spark ignition, and new cylinder liners, pistons and piston rings. Low engine speed torque is understood to be inferior to the parent diesel engine, so overall gearing is lowered to compensate.

An 800 km range is claimed – twice that of battery electric trucks – and refuelling is almost as fast as with diesel. In contrast, battery-electric trucks need hours to recharge, and payload is severely compromised by battery weight. Ron Borsboom, director of product development at DAF, said: “To cross the Alps you need 500 hp power, and due to distance and infrastructure that is now only possible with a combustion engine.”

Of the other mainstream European truck manufacturers, only MAN is known to be involved in a similar project, although its role as lead engine developer for Traton could see the technology cascaded down to Scania and Navistar. Remaining marques are concentrating on battery and fuel-cell solutions to power electric drivetrains.

But in the UK, Cummins and JCB are separately working on programmes to adapt existing diesel engine designs to run on hydrogen, while elsewhere in the world Deutz, Caterpillar and China Yuchai all have hydrogen-fuelled ICE projects underway.

Most of these companies have also been involved with projects to power electric vehicles or plant using hydrogen fuel cells, but it seems that growing realisations of the cost and fragility of such systems have convinced manufacturers to return to internal combustion. Not all the projects underway are primarily intended for truck and bus, but the technology would certainly be transferable from, for instance, static and mobile plant, to heavy-duty road vehicles.

Construction and agriculture equipment specialist JCB has taken the covers off a project which it says may see hydrogen-powered engines in commercial use at the end of this year. While JCB engines are unlikely to find their way into road vehicles in the near future, its hydrogen project illustrates how hydrogen engines could be developed to replace diesels in heavy-duty road-going applications.

Construction and agriculture equipment specialist JCB has taken the covers off a project which it says may see hydrogen-powered engines in commercial use at the end of this year. While JCB engines are unlikely to find their way into road vehicles in the near future, its hydrogen project illustrates how hydrogen engines could be developed to replace diesels in heavy-duty road-going applications.

With the exception of the pistons, its hydrogen engines use components common with the diesel engine from the cylinder-head down. Packaging the hydrogen engine into a machine designed for diesel is thus relatively easy.

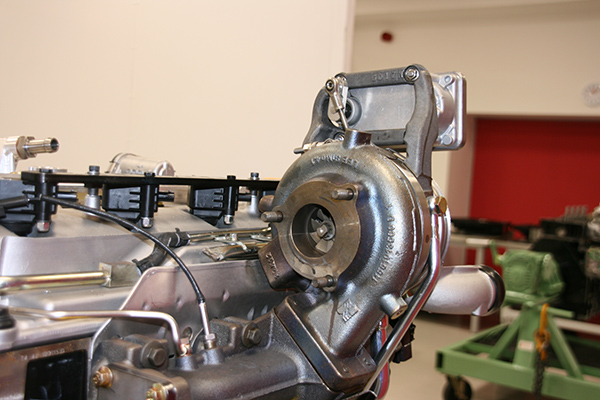

Spark ignition is used to ignite the directly-injected hydrogen, and the engine’s compression ratio is reduced accordingly. A large variable-geometry turbo-charger (twice the size of the standard diesel unit) is specified for two reasons: one being that hydrogen does not disperse well in a confined cylinder so the momentum of a big slug of air is needed to mix the gas, and the other is that a generous supply of controllable intake air allows the torque characteristics of a conventional diesel engine to be replicated.

The exhaust gas consists mostly of water vapour from the combination of hydrogen and atmospheric oxygen. JCB says that NOx production during combustion is so low that no form of downstream exhaust treatment is required. Puffs of steam can be seen exiting the exhaust stacks of hydrogen-powered machines. The engines also run quieter than the equivalent diesel as there is no combustion ‘knock’.

The exhaust gas consists mostly of water vapour from the combination of hydrogen and atmospheric oxygen. JCB says that NOx production during combustion is so low that no form of downstream exhaust treatment is required. Puffs of steam can be seen exiting the exhaust stacks of hydrogen-powered machines. The engines also run quieter than the equivalent diesel as there is no combustion ‘knock’.

Because there is no carbon in the combustion process, the lubricant of the hydrogen engine remains visually clean. However, water vapour passes the piston rings during the combustion process, and a specialist oil is required that can cope with this without emulsifying. Water contamination also strips additives from the lubricant, so regular oil changes are still required.

American engine manufacturer Cummins is using UK government funding to develop hydrogen combustion engines, based on its 6.7 and 15-litre engines, which would cover a broad spectrum of applications from city buses to long-haul heavy transport.

It said the engines will use new technologies to improve power density, reduce friction and improve thermal efficiency, avoiding the typical performance limitations and efficiency compromises associated with converting diesel or natural gas engines to hydrogen fuel. Following the proof-of-concept testing, the company plans to evaluate the engine in a variety of on- and off-highway applications, supporting the company’s efforts to accelerate the decarbonisation of commercial vehicles.

The hydrogen engines can use green hydrogen fuel, produced by Cummins-manufactured electrolisers, emitting near zero CO2 emissions through the tailpipe and near zero levels of NOx.

Caterpillar, a rival of both JCB and Cummins, although not currently active in the heavy-truck market, plans to have hydrogen-powered gensets available for demonstration by the end of the year.

Deutz’s TCG 7.8 H2 hydrogen engine is said to have passed initial bench tests with flying colours and is scheduled to go into full production in 2024. The six-cylinder TCG 7.8 H2 is based on an existing engine design and is rated at 200 kW. It will power electrical generators in service with a utility company before the end of this year.

Possibly the most advanced hydrogen engine so far is being developed in China. China Yuchai International, a leading manufacturer and distributor of engines for on- and off-road applications in China through its main operating subsidiary, Guangxi Yuchai Machinery Company Limited, announced that the company’s YCK05 hydrogen-powered engine achieved stable ignition and operation in a demonstration at the Beijing Institute of Technology at the end of last year. The YCK05 engine is the first hydrogen engine for commercial vehicles in China, the world’s largest truck market.

The YCK05 hydrogen-powered engine adopts a number of advanced special technologies such as high-pressure multi-point inlet injection technology, high-efficiency low-inertia turbocharging, and high-efficiency lean-burn combustion technology. The engine design upgrades the engine structure from its diesel parent, with new ignition and fuel-injection systems.

In light-duty applications, Toyota, Mazda and Subaru, together with motorcycle and engine manufacturers Yamaha and Kawasaki, have joined forces to form a Team Japan dedicated to the future of internal combustion engines. Besides hydrogen, the companies are developing engines burning biomass-derived synthetic liquid fuels.

Information source; http://transportoperator.co.uk/2022/02/09/hydrogen...

Morris Lubricants is supporting the preservation of a “celebrity” Class 37 diesel-electric locomotive.

Direct Rail Services (DRS) has placed loco 37714 into the care of the Heavy Tractor Group to operate and maintain at the Great Central Railway.

One of only four surviving 37/7 class locos, it has attracted interest from rail fans across the country, including Morris Lubricants. The Shrewsbury-based company has supplied lubricants from its Locomax range for the loco in return for having its name on 37714.

The new livery has gone down a storm on social media with trainspotters travelling from all over the country to photograph the loco.

Keiron Thorogood, Morris Lubricants’ rail account manager, said the high level of interest generated by having the company’s livery on the loco was completely unexpected and it had become a “bit of a celebrity”.

“The fact that the loco was already painted in our colour, DRS blue, was very opportune,” he added. “Trainspotters have been champing at the bit to come and see it in a different livery.

“The Heavy Tractor Group asked for the company’s assistance with our Lodexol MTL traction motor grease and we were happy to support the project.

“My job within the company started within heritage railways and my passion for trains. Morris Lubricants is already well established as a leader in the heritage sector and is now perfectly placed to be a major player in the mainline rail industry with our Locomax range of quality engine and gear casing oils and traction motor greases.

“The rail industry, which uses large volumes of lubricants, is a huge market for the company and we have the product range to service it. We want to be the number one supplier of lubricants to heritage and mainline rail.”

He explained that loco 37714, which was built by English Electric in 1961, is due to be repainted in the new year and is likely to tour the country and operate on heritage railway lines in the future.

The Class 37 locos, which were originally ordered as part of British Rail’s modernisation plan, became a familiar sight on many parts of the rail network, particularly on Inter-City services in East Anglia and within Scotland.

Nicknamed ‘Tractors’ because of the agricultural sound of the diesel engine, the locos also operated on secondary and inter-regional services for many years and were designed for both passenger and freight work.

New Product Bulletin: Morris Lubricants Workshop PRO Aerosol Range

The Morris Lubricants Workshop PRO aerosol range is now live and available for purchase.

The Workshop PRO range includes the new-look flagship MD4 multipurpose maintenance spray to fully synthetic chain lubricants and solvent cleaners. The range offers superior performance across a multitude of demanding applications, the must have accompaniment to any maintenance workshop.

New Product: Morris Lubricants MLR Racing Brake Fluid

MLR Racing Brake Fluid has been specially formulated to maximise performance under the extreme temperature conditions experienced in motorsport. The fluid maintains its integrity under the most arduous of operating scenarios ensuring positive and effective braking. MLR Racing Brake Fluid is blended with special additives that prevent fluid oxidation, rust and the swelling of the piston seals used in conventional brake systems and is compatible with all other non-mineral brake fluids manufactured to the same specifications. MLR Racing Brake Fluid is suitable for use in all brake and clutch systems, where a non-mineral oil grade has been specified meeting the performance levels listed below. Always check manufacturer’s handbooks for the correct fluid type as mis-application will impair brake operation and pose a threat to vehicle safety.

Morris Lubricants Automotive Engine Oil Brand Updates - November 2016

IMPORTANT: Automotive Engine Oil Brand Updates - November 2016

IMPORTANT: Automotive Engine Oil Brand Updates - November 2016

November 2016 ushers in an important milestone for Morris Lubricants’ automotive engine oil range as it makes the transition to the long

established and respected MULTIVIS brand name.

Why are we changing?

Increasingly complex automotive engine oil formulation and rate of innovation called for a new naming and coding structure that provides both longevity and consistency to the range. Secondly the MULTIVIS brand offers maximum trademark protection for over 80 emerging and competitive international markets in which we now proudly operate.

Assisting with the transition

Part numbers will remain the same across all grades and packaging sizes. New barcodes have been applied across 1 and 5 litre pack sizes. All 25 and 205 litre packaging will contain previous names to assist with familiarity. In conjunction with this all invoices, delivery notes, technical datasheets and supporting marketing literature will detail previous product names until the end of 2017. Our online lubricant selector tool www.whatoildoineed.com will also contain previous names to assist with the consumption of current branded stock that you may hold.

Morris Lubricants fuels family’s sidecar racing success

It would be fair to say that sidecar racing is in the genes of the Wirral-based Founds family. It all started more than 30 years ago with dad Des, who competed in the British championships as well as the family’s beloved Isle of Man TT.

Des is still keenly involved but now supports his sons, Pete, 38 and Alan, 33, as manager of Team Founds Racing. He’s a very proud dad, as Alan won the British F2 Sidecar Championship last year and now older brother Pete is bidding to follow in his footsteps, as he currently leads this year’s table at the half-way stage.

All three men have the distinction of a podium finished in a TT race, with Pete having a second place to his name this year while both Des and Alan have finished third.

Team Founds Racing is very much a family affair, with sister, Hannah, handling the public relations and social media and uncle Ron a key member of the support team.

Eldest brother Chris also used to compete, with Pete, at that point, opting to man the sidecar. They finished 11th in the World Sidecar Championships. Youngest brother Alan and family friend Tom Peters continued the racing tradition and finished last season as British F2 champions.

Now Pete, with passenger Jevan Walmsley, are targeting Alan’s title after coming runner up in the British F2 Cup last year. Pete's racing career stretches back to 1993 when he started out as a passenger and continued in the sidecar until 2007. He is now having his most memorable year to date, as he and Jevan have taken the British Championship by storm and also finished second in a TT race in May.

“My main ambition was to make it on to the podium at the TT, which we managed earlier this year,” said Pete, who lives in Knutsford. “We now need to go back and prove that it was not a fluke and it would be great to keep the British Championship in the family.

“I was brought up going to the Isle of Man because dad raced there for 25 years. I didn’t know there was another type of holiday until I had a girlfriend!”

Alan, who began racing at the age of 16 as a passenger for both his dad and Chris, has this year been joined by Aki Aalto from Finland in a new bike and sidecar outfit. It has been a development season for them, as they have been breaking in the bike with plans to contest the British Championship again next year.

As for rivalry between the brothers, Alan says: “On the track, there are no holds barred, but off the track, we share everything.”

Now the brothers are eagerly waiting to see what the ruling body for sidecar racing decides for next season, with a chance that all bikes will be restricted to 600cc in both the British and World Championships.

The brothers are delighted to be ambassadors for the Morris Lubricants Motorsport Programme, which sees the Shrewsbury-based company provide them with all the lubricants they need for racing. In return, they fly the Morris Lubricants flag and promote the company’s quality lubricants at every opportunity.

Britain’s leading family owned lubricants business has had long association with Des and his sons and recently welcomed Team Founds Racing to the company’s headquarters for a photoshoot and mid-season progress report.

“We feel very proud to be representing Morris Lubricants because the company has a lot of heritage and we are passionate about the association,” said Pete, who is a power station engineer when not hurtling at up to 155mph around a track. “We are often asked what oils we use and are proud to say that we’ve always used Morris Lubricants because they have been successful for us.”

Alan, an aeronautical engineer from Little Neston, chips in with: “It’s great for us as a family to be involved with another family organisation. All the Morris Lubricants products that we use, including the chain lube, are fantastic. We have now also converted our engine tuner who has seen the quality of the lubricants at first hand and sings their praises.”

Last word goes to Des who is justifiably proud of his sons’ achievements. “I am gobsmacked at how quick they are,” he said. “Both have proved their TT prowess and they’re 10mph faster around the course than I was.

“I would like to think that I have made a small contribution to their success. The fact that all three of us have been on the TT podium is fantastic.”

Craig Bastable, Morris Lubricants’ marketing manager, said: “We are proud to be associated with Des and his sons who are fantastic ambassadors for our top quality products. The Morris Lubricants Racing (MLR) programme aims to not only help racers like Pete and Alan to achieve success, but also increase awareness of our brand in all areas of British motorsport.”